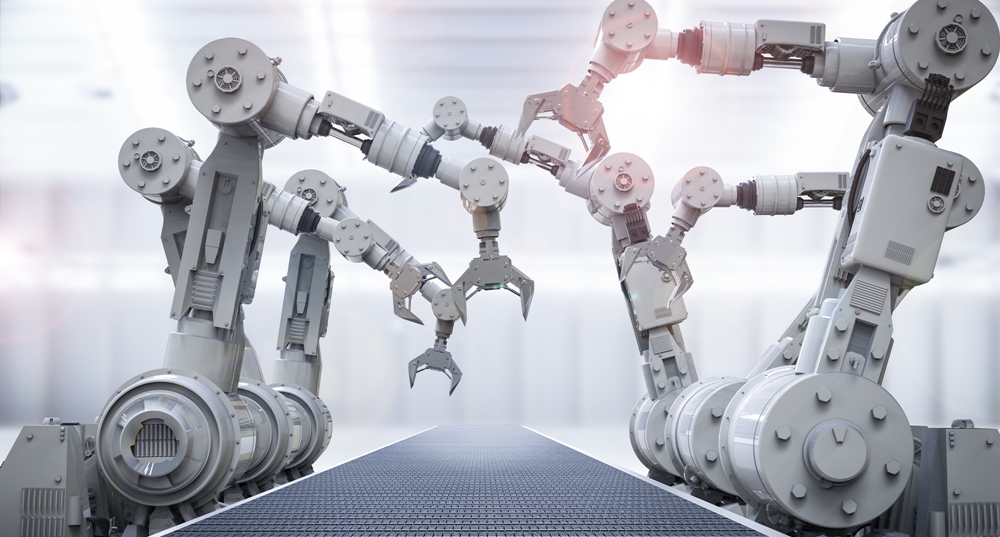

In recent years, robots have become an increasingly popular tool for manufacturing companies. They offer a variety of benefits, including increased efficiency, precision, and safety. The role of robots in manufacturing is only expected to grow with technological evolution

One of the key benefits of using robots in manufacturing is increased efficiency. Robots can perform tasks at a much faster rate than humans, and they don’t require breaks or rest periods. This means that they can work around the clock, increasing production rates and reducing costs.

Robots are also highly precise, which is important in many manufacturing processes. They can be programmed to perform repetitive tasks with a high degree of accuracy, ensuring consistent quality in the final product. This is particularly important in industries such as automotive manufacturing, where even small deviations from the design specifications can cause significant problems.

In addition to efficiency and precision, robots can also improve safety in the workplace. They can be used to perform dangerous tasks, such as working with hazardous materials or in high-risk environments. This also reduces the risk of accidents and injuries that can cause costly downtime.

Another benefit of using robots in manufacturing is the ability to adapt to changing demands. Robots can be reprogrammed and reconfigured to perform different tasks, allowing manufacturers to quickly respond to changes in the market shifts. This flexibility is crucial in today’s fast-paced business environment, where companies need to be agile and responsive to stay competitive.

In India, the use of robots in manufacturing has been steadily increasing in recent years. According to a report by the International Federation of Robotics (IFR), India’s robot sales grew by 54% in 2023. This signifies that robots are becoming an increasingly popular tool for Indian manufacturers.

Several Indian companies are leading the way in the adoption of robotics technology. For example, Tata Motors has installed over 300 robots in its Pune plant for tasks like welding, painting, and assembly. Mahindra & Mahindra has also incorporated robots into its manufacturing processes, with over 200 robots currently in use in its factories.

Other companies that have embraced robotics technology in India include Larsen & Toubro, Bajaj Auto, and Maruti Suzuki. These companies have used robots for a range of tasks, including material handling, assembly, and quality control.

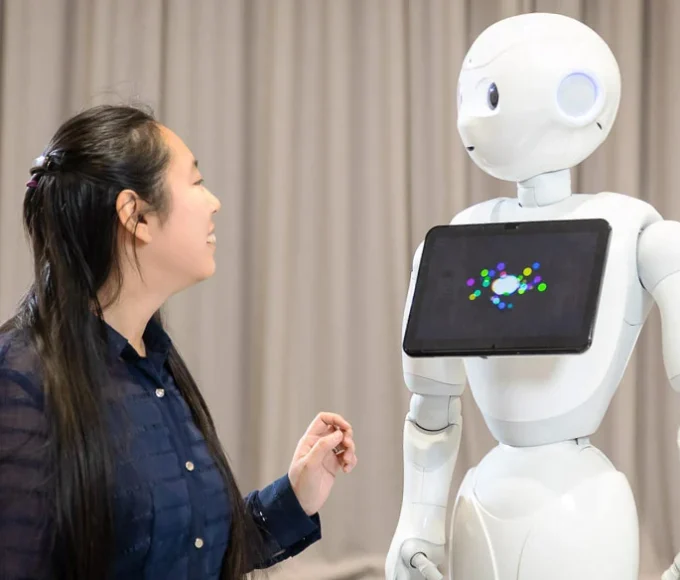

In conclusion, the use of robots in manufacturing is a growing trend globally and in India. The benefits of improved efficiency, precision, and safety make robots an attractive option for manufacturers looking to stay competitive in today’s fast-paced business environment.

With several Indian companies already incorporating robotics technology into their operations, it’s clear that robots will play an increasingly important role in the future of manufacturing in India.

Leave a comment