Robots have revolutionized the manufacturing industry in recent years, making production faster, safer, and more efficient. Today, there are several types of robots that are widely used in manufacturing. In this blog, we’ll explore the different types of robots used in manufacturing today.

Industrial Robots:

Industrial robots are the most common type of robot used in manufacturing. These robots are designed to perform repetitive tasks with high precision and accuracy. They are commonly used in applications such as welding, assembly, painting, and material handling. Industrial robots can be programmed to perform specific tasks, and they can work 24/7 without taking breaks.

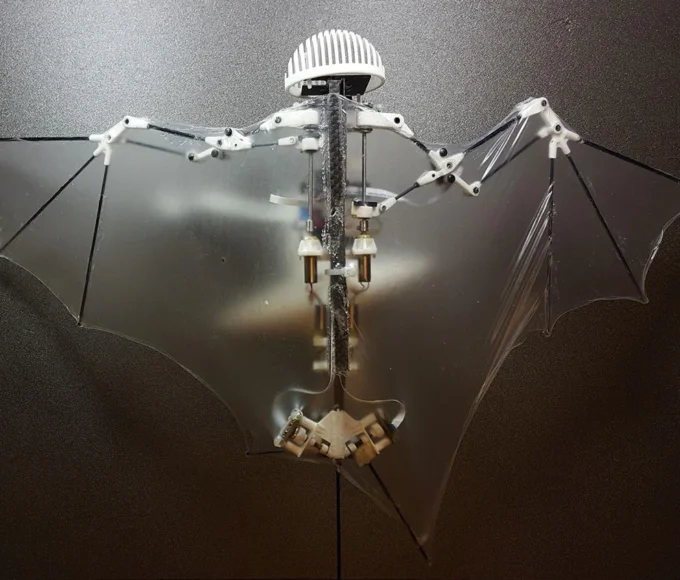

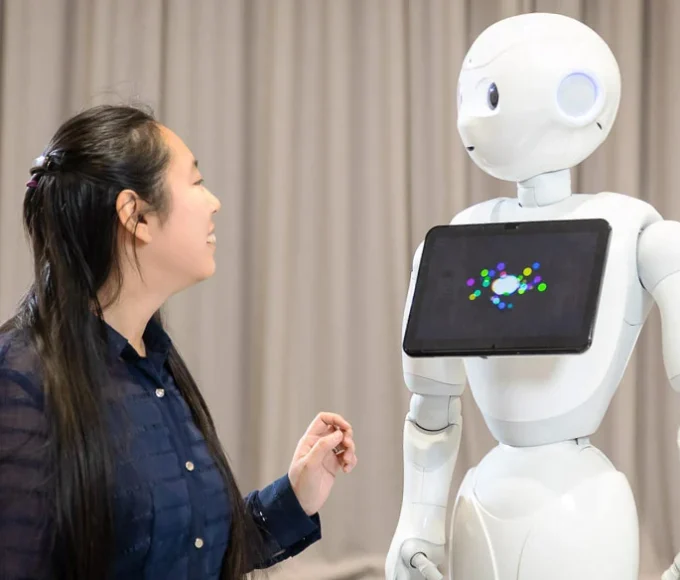

Collaborative Robots:

Collaborative robots, also known as cobots, are designed to work alongside humans in a manufacturing environment. These robots are smaller and more flexible than industrial robots, and they are equipped with sensors that allow them to detect the presence of humans. Cobots are often used in applications where human and robot interaction is required, such as in assembly and packaging.

Autonomous Mobile Robots:

Autonomous mobile robots (AMRs) are robots that can move around a manufacturing facility without human intervention. These robots are equipped with sensors and navigation systems that allow them to move safely and efficiently around obstacles. AMRs are commonly used for material handling tasks such as transporting raw materials, finished products, and equipment.

SCARA Robots:

SCARA (Selective Compliance Assembly Robot Arm) robots are designed for high-speed assembly and material handling tasks. These robots have a vertical axis and a horizontal arm that can move in a circular motion. They are commonly used in applications such as packaging, assembly, and pick-and-place operations.

Delta Robots:

Delta robots are designed for high-speed pick-and-place applications. These robots have a unique structure consisting of three arms that are connected to a central joint. Delta robots are commonly used in industries such as food and beverage, pharmaceuticals, and electronics manufacturing.

Articulated Robots:

Articulated robots are designed with multiple joints that allow them to move in a variety of directions. These robots are commonly used in applications such as welding, painting, and material handling. They are known for their flexibility and ability to perform complex tasks.

According to a recent report by ResearchAndMarkets, the Indian robotics market is expected to reach $5.5 billion by 2026, growing at a CAGR of 20.8% from 2021 to 2026. The Indian government’s focus on the “Make in India” initiative, automation of various industries, and the growth of the e-commerce industry are among the factors driving this growth. Furthermore, India’s automobile industry, which is expected to grow significantly over the next few years, is also expected to boost the demand for robots in the country.

In conclusion, the use of robots in manufacturing has led to increased productivity, efficiency, and safety in the workplace. India’s rapidly growing robotics market indicates the country’s eagerness to adopt this technology and improve its manufacturing capabilities.

As technology continues to advance, we can expect to see more advanced and sophisticated robots being developed for use in the manufacturing industry.

%s Comment