Over the years, we have witnessed remarkable advancements in the industrial landscape, as automation has transformed traditional factories into smart factories. This evolution has been made possible by the integration of machine learning techniques into industrial automation processes. Machine learning has revolutionized the way factories operate, enhancing productivity, efficiency, and safety.

The traditional factory model relied heavily on manual labour, where human operators performed repetitive tasks and managed production processes. Although this system served its purpose, it often encountered challenges such as inefficiencies, errors, and limited scalability. However, with the advent of technology, the industrial sector has experienced a remarkable transformation.

Machine learning algorithms are designed to analyse vast amounts of data, recognize patterns, and make predictions or decisions without explicit programming. When applied to industrial automation, these algorithms enable machines to learn from data and continuously improve their performance, leading to optimized production processes.

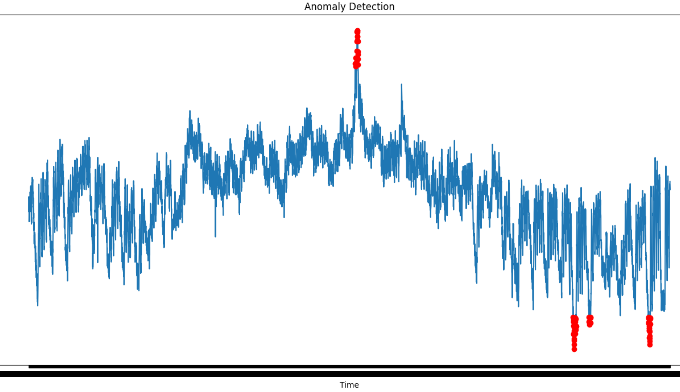

One of the key applications of machine learning in industrial automation is predictive maintenance. By analyzing real-time sensor data from machinery and equipment, ML algorithms can identify patterns and indicators of potential failures or maintenance needs. This proactive approach helps factories reduce downtime, prevent costly breakdowns, and optimize maintenance schedules. By accurately predicting maintenance requirements, factories can schedule maintenance activities during planned downtime, ensuring minimal disruption to production.

Quality control is another critical area where machine learning has made significant strides. Traditional quality control methods often involved manual inspection, which was time-consuming and prone to errors. Machine learning algorithms can be trained on historical data to recognize patterns associated with defective products. By analyzing sensor data, images, or other relevant data sources, these algorithms can detect anomalies in real-time, identifying defective products with higher accuracy and speed. This not only improves product quality but also reduces waste and improves overall operational efficiency.

Machine learning also plays a vital role in optimizing production processes. Through the analysis of large volumes of data, including historical production data, sensor data, and external factors, machine learning algorithms can identify patterns and correlations that humans may overlook. This enables factories to identify bottlenecks, optimize workflows, and improve resource allocation. By continuously monitoring and adjusting production parameters based on real-time data, smart factories can maximize production output while minimizing energy consumption and waste.

Furthermore, machine learning facilitates the integration of robots and autonomous systems into industrial processes. With the ability to learn from data and adapt to changing conditions, robots can perform complex tasks with precision and efficiency. Machine learning algorithms enable robots to recognize and manipulate objects, navigate through dynamic environments, and even safely collaborate with human workers. This integration with robotics opens up new possibilities for increased automation, productivity, and flexibility in industrial settings.

Startup in this domain:

Superprocure: They one of the leading logistics and supply chain management solutions providers for top manufacturing and infra companies. Their industry-recognized products, such as Spot Freight Negotiation, Trip Management Systems, Contract Management, Dispatch Planning, and Freight Accounting solutions, resolve critical industry problems associated with logistics and supply chain management.

However, the implementation of industrial automation does come with challenges. Data collection, management, and security are critical considerations. Smart factories generate vast amounts of data, and establishing robust data infrastructure is essential to harness the full potential of machine learning. Furthermore, ensuring the security and privacy of sensitive data is paramount, as industrial systems are prime targets for cyber threats.

We have entered in a new era of industrial automation, transforming traditional factories into smart factories. Through applications such as predictive maintenance, quality control, production optimization, and robotic integration, machine learning algorithms enable factories to operate more efficiently, effectively, and safely.

As technology continues to advance, we can expect machine learning to play an even more significant role in shaping the future of industrial automation, paving the way for increased productivity and innovation in the manufacturing sector.

Leave a comment